Seed HB, Booker JR (1977) Stabilization of potentially liquefiable sand deposits using gravel drain systems. Presse de l’école nationale des Ponts et chaussées, Paris Zhang K, Wu YS, Pruess K (2008) User’s guide for TOUGH2-MP-a massively parallel version of the TOUGH2 code.Dhouib A, Blondeau F (2005) Colonnes ballastées (techniques de mise en œuvre, domaine d’application, comportement, justification, contrôle, axes de recherches et développement). In: Proceedings of the SPE Europec/EAGE annual conference, SPE 94128 Van der Meer LGH, Kreft E, Geel C, Hartman J (2005) K12-B: a test site for CO2 storage and enhanced gas recovery. Rutqvist J, Wu YS, Tsang CF, Bodvarsson G (2002) A modeling approach for analysis of coupled multiphase fluid flow, heat transfer, and deformation in fractured porous rock. Rutqvist J, Tsang CF (2002) A study of caprock hydromechanical changes associated with CO2 injection into a brine aquifer. Lawrence Berkeley National Laboratory, LBNL-56589 Oldenburg CM, Moridis GJ, Spycher N, Pruess K (2004) EOS7C Version 1.0: TOUGH2 module for carbon dioxide or nitrogen in natural gas (methane) reservoirs. In: Proceedings of TOUGH symposium 2003, LBNL, Berkeley, California Oldenburg CM (2003) Carbon sequestration in natural gas reservoirs: enhanced gas recovery and natural gas storage. Martens S, Kempka T, Liebscher A, Lueth S, Moeller F, Myrttinen A, Norden B, Schmidt-Hattenberger C, Zimmer M, Kuehn M (2012) Europe’s longest-operating on-shore CO 2 storage site at Ketzin, Germany: a progress report after three years of injection. Kühn M, Tesmer M, Pilz P, Meyer R, Reinicke K, Förster A, Kolditz O, Schäfer D (2012) CLEAN: project overview on CO 2 large-scale enhanced gas recovery in the Altmark natural gas field (Germany). Kühn M, Förster A, Großmann J, Meyer R, Reinicke R, Schäfer D, Wendel H (2010) CLEAN: preparing for a CO 2-based enhanced gas recovery in a depleted gas field in Germany.

Numbers green flac3d code#

Hou Z, Gou Y, Taron J, Gorke UJ, Kolditz O (2012b) Thermo-hydro-mechanical modeling of carbon dioxide injection for enhanced gas-recovery (CO2-EGR): a benchmarking study for code comparison. Hou Z, Wundram L, Gou Y (2012a) Abschlussbericht zum F&E Verbundvorhaben CLEAN für Themenverbund 2.4, 3.1.2 und 3.2.2 Masterarbeit am Institut für Erdöl- und Erdgastechnik der TU Clausthal Gou Y (2011) Untersuchungen zu THM-gekoppelten Reaktionen der Speicherformationen und des Deckgebirges bei CO 2-EGR mit dem integrierten Code TOUGH2–FLAC3D. GDF SUEZ (2008) Altensalzwedel-Geomodellierung, Präsentation im Rahmen des CLEAN projektes-Stand der Arbeit, Meeting in Berlin, Abschlussbericht zum F&E Verbundvorhaben CLEAN Ganzer L, Reitenbach V, Albrecht D, Awemo KN, Singhe AT, Wienand J (2011) Bestimmung der Speicher- und Fließparameter sowie Prozesssimulation des CO2-Pilottests. This former flow field, including CO 2 injection/CH 4 production rate during CO 2-EGR and fault directions and intensity are the most important factors affecting the CO 2 transport. It could be concluded that the previous flow field was established during the primary gas production history. Even then the CO 2 did not reach the production well S14 after 2 years of injection. With the injection rate doubled the average pressure increased by 5.3 bar. The deformation was small (elastic) and caprock integrity was not affected. The largest uplift (1 mm) occurred at the bottom of the caprock. After 2 years of CO 2 injection, the reservoir pressure increased by 2.5 bar, which is beneficial for gas recovery. It reached the observation wells S1 and S16 after 2 years, but no breakthrough occurred in the production well. Simulation results show that CO 2 tends to migrate toward the production well S14 along a NW–SE fault. Some sensitivity analyses were also carried out. In the simulation, 100,000 t CO 2 was injected in the reservoir through well S13 within 2 years, while gas was produced from the well S14. The model is heterogeneous and discretized into 26,015 grid blocks.

A multi-layered 3D model (4.4 km × 2 km × 1 km) which consists of the whole reservoir, caprock and base rock was generated based on a history-matched PETREL model, originally built by GDF SUEZ E&P Deutschland GmbH for Altmark natural gas field. In order to consider the gas mixing process, EOS7C was implemented in TOUGH2MP.

Numbers green flac3d simulator#

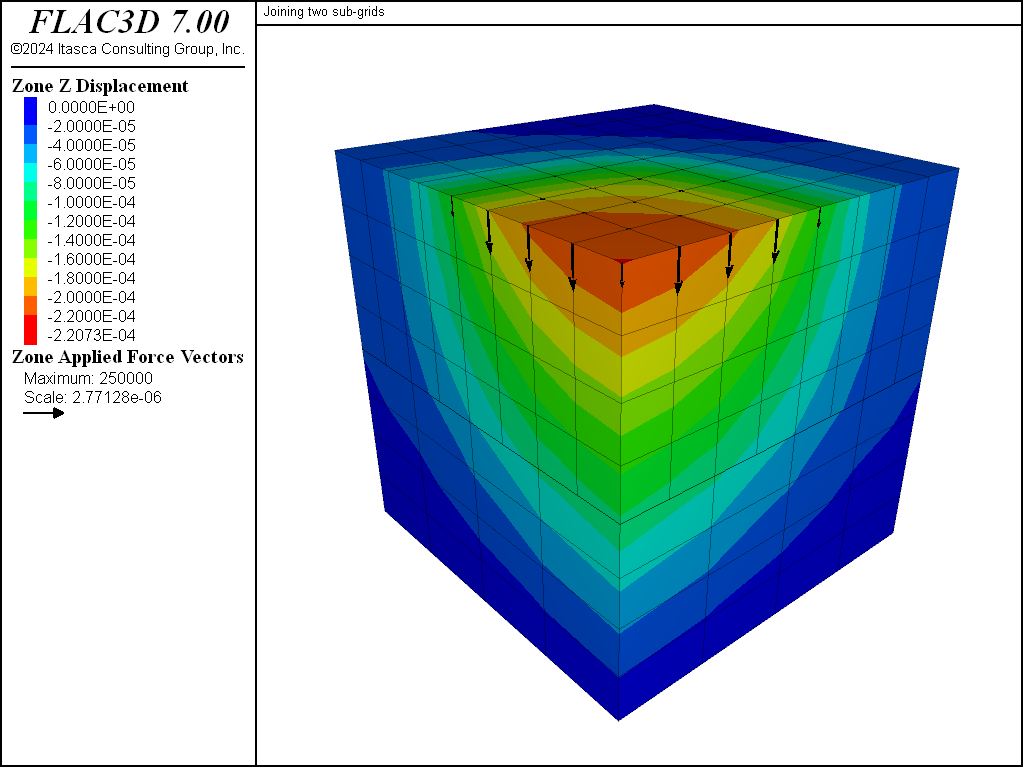

The hydro-mechanical coupled simulations were run using a linked simulator TOUGH2MP-FLAC3D. This paper studied the CO 2-EGR in Altmark natural gas field with numerical simulations.

0 kommentar(er)

0 kommentar(er)